How China’s Auto Industry Evolved from Zero to Leader

Advertisements

In the past, discussions of the Chinese automotive industry often evoked a sense of uncertainty and skepticism. Many people might have thought that domestic brands were too few and far between, failing to make a significant mark on the global stage. However, the landscape of the Chinese automotive sector has undergone radical changes over the years, reaching a point where it now calls for a fresh perspective from the international audience.

A glimpse into the latest statistics reveals the remarkable transformation of this industry. Last year, China’s production and sales of automobiles surged past 26 million units, securing the top spot worldwide. This figure is nearly double that of the United States and six times that of Japan, a notable change considering that just a decade ago, China’s car sales were a mere fraction of those in the U.S. This remarkable turnaround is nothing short of impressive.

Some may question the validity of these high sales figures, arguing that they stem from joint ventures or firms that are not entirely Chinese in origin. However, the raw numbers themselves signify a monumental leap for China's automotive sector. Despite its initial reliance on foreign technologies, the influx of manufacturers establishing assembly lines in China has paved the way for a buildup of skills, knowledge, and technical prowess.

Manufacturing automobiles is a uniquely complex endeavor, often cited as one of the more challenging disciplines within the manufacturing sector. An average vehicle consists of over a thousand individual components and is designed for a lifespan that can exceed a decade. Manufacturers are tasked with melding numerous small parts, each costing an average of just a few dollars, into a cohesive, reliable system that functions dependably for many years.

While aircraft manufacturers can also achieve high reliability, they often cannot match the automotive sector's ability to lower costs to unprecedented levels, primarily due to the difference in scale. An automobile factory can produce several million cars a year, a stark contrast to the production of airplanes.

This capacity for mass production has spurred the development of sophisticated manufacturing management systems and stringent cost control processes in the automotive industry. In an effort to minimize working capital tied up in inventory and boost reaction times, many automotive manufacturers cluster their supply chains within specific regions. The breadth of industries involved in automotive production—ranging from metallurgy to electronics—has a substantial ripple effect on the national economy, contributing to its reputation as the "crown jewel of human industry."

Years ago, countless internal combustion vehicle manufacturers recognized the potential of the Chinese consumer market, leading them to locate their manufacturing plants within the country. Setting up shop in China necessitated a comprehensive shift in the supply chain, resulting in an uptick of local talent—both in the workforce and management—taking part in operations. This transition has enabled China to steadily accumulate knowledge and experience, setting the stage for future advancements.

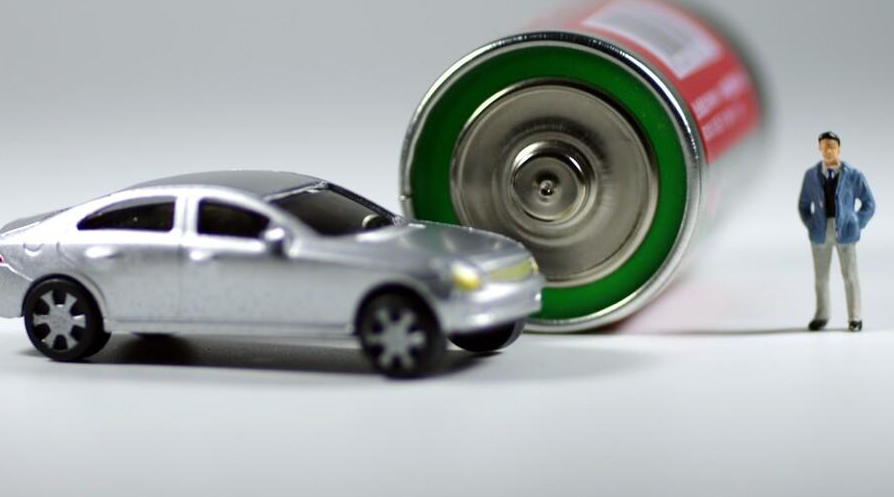

A prominent trend currently shaping the automotive sphere is the shift towards electric vehicles (EVs). In the global race for electrification, China and the United States have emerged as front-runners. Thanks to years of investment and development, several Chinese firms now boast production capacities that can stand toe-to-toe with internationally recognized OEMs.

Take CATL, for example. This company has positioned itself as a global leader in the production of lithium batteries for electric vehicles, commanding nearly 50% of the global market share. Their innovative advancements in battery efficiency have been pivotal in enhancing the driving range of EVs. Most components of electric vehicles being produced in China are now localized, with some technologies even leading the world.

Unlike conventional vehicles where incumbents often have significant technological advantages, the landscape of EVs is relatively even. Countries around the globe find themselves on level footing when it comes to developing the technology necessary for electric mobility.

To accelerate the growth of the EV sector, China initiated comprehensive subsidy programs starting in 2010. These subsidies were instrumental in allowing automotive companies and researchers to transition swiftly through the developmental phase, establishing themselves as key players in the evolving market. This initiative has undeniably paid off, with China now making significant strides in its fleet of electric vehicles, effectively leapfrogging ahead of other nations.

Countries like Japan and Germany, once considered heavyweights in the automotive sector, are now finding themselves lagging in the electric vehicle race. China's automotive exports skyrocketed by more than 100% last year, positioning the country as the second-largest auto exporting nation behind Japan, and perhaps on the verge of claiming the top spot soon.

The advantages of electric vehicles extend beyond mere fuel efficiency and environmental concerns. The performance of EVs has seen remarkable advancements, and with ongoing technological evolution, the potential for future improvements remains vast. During this latest technological revolution in the automotive space, China is not merely participating but is taking a lead role.

The statistics are staggering: China’s sales of electric vehicles account for over 50% of the total global market. With the exception of Tesla, the bulk of vehicles sold are produced by domestic manufacturers. In the paramount supply chain for vehicle batteries, Chinese companies such as CATL, BYD, AVIC Lithium Battery, and Guoxuan High-tech share over 80% of the global market, dominating the sector.

For decades, the Chinese automotive industry evolved from being a contract assembler to a powerhouse in its own right, cultivating a strong manufacturing supply chain while transitioning through this transformative phase. When the shift toward electric vehicles materialized, China seized the opportunity decisively and accelerated ahead of traditional leaders in automotive engineering.

This transformation reflects not only the achievements of the Chinese automotive sector but also embodies the dynamic progress of its overall manufacturing landscape. Even in areas that may not have been front and center in public discourse, various industries are silently forging ahead. It is reasonable to conclude that as all these sectors continue to advance, China is poised to cement its place on the global stage with even greater distinction.

Leave A Comment